Fully automatic systems are same as semiautomatic systems, except the complete operation, from the feeding through the end of the filtration cycle, is begun through a single "start" push button in central control panel.

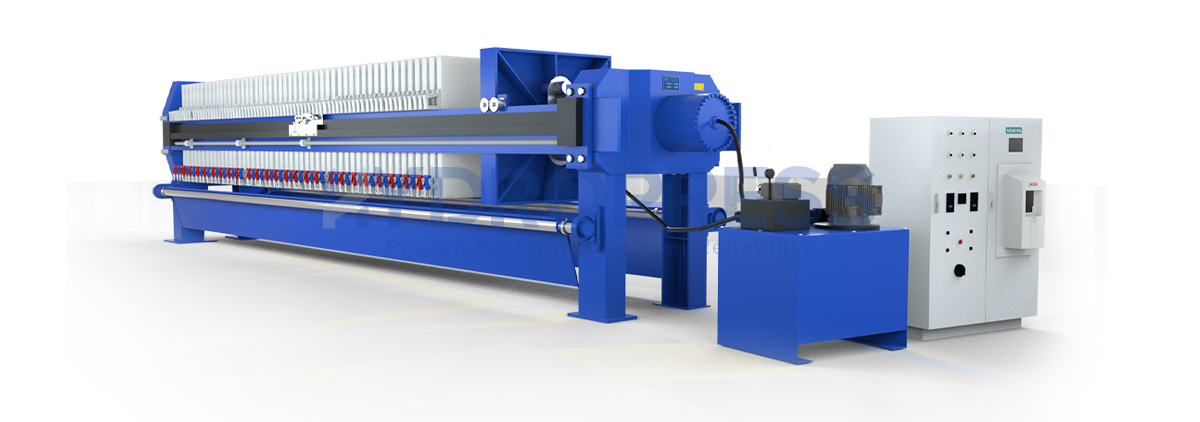

We manufacture fully automated advanced filter press with plate shifting and plate shaker for auto cake discharge along with PLC based electrical control panel and pneumatically operated control valves, flow sensor, and hydraulically operated bomb door drip tray.

Our fully automatic filter press simple cake removal system is available with conventional fixed-volume and recessed-chamber plate filter presses. It includes a programmable logic controller (PLC) and can be supplemented with a local control panel, CRT, or touch-screen panel.