The semi-automatic system has a central control panel where each sequence steps are activated by the operator.

All valves will be manually opened and closed.

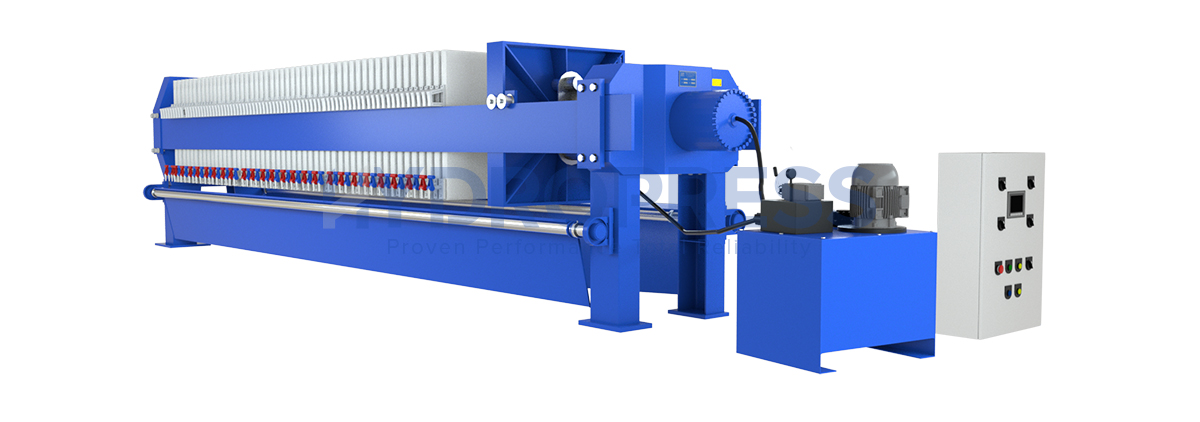

The working of a semi-automatic filter press is similar to a manual filter press. However, some of the process is automated. We manufacture semi-automatic plate filter press with electro mechanical plate shifting device.

The filter press comprises of a hydraulic cylinder. The main function of the cylinder is to create and release pressure.

The offered filter press has two mechanisms as side shifting mechanism and overhead plate shifting mechanism. Our technocrats can fabricate

customised mechanical filter presses as per customers’ requirements. Clients can avail these products at industry competitive prices.

Using a semi-automatic filter press allows for equal distribution of pressure in chambers, semi-automatic cycle and is 70% efficient compared to a manual filter press.